Txheej ntawm taps

1, chav oxidation: coj mus rhaub rau hauv qhov kub siab dej vapor, qhov chaw ntawm kev tsim cov oxide zaj duab xis, cov cua txias adsorption zoo, tuaj yeem ua lub luag haujlwm hauv kev txo kev sib txhuam, thaum tiv thaiv cov kais dej thiab cov khoom txiav ntawm daim ntawv cog lus, tsim nyog. rau kev ua cov hlau me me.

2, nitriding kev kho mob: kais nto nitriding, tsim ib txheej txheej hardening, haum rau ua hlau cam khwb cia hlau, cam khwb cia txhuas thiab lwm yam ntaub ntawv ntawm lub cuab tam hnav.

3, chav + nitriding: kev zoo ntawm ob qho saum toj no.

4, TiN: txheej xim daj xim, zoo txheej hardness thiab lubrication, thiab txheej adhesion kev ua tau zoo, haum rau kev ua cov ntaub ntawv feem ntau.

5, TiCN: xiav grey txheej, hardness txog 3000HV, kub tsis kam ntawm 400 ° C.

6, TiN + TiCN: txheej xim daj tsaus, nrog cov txheej txheem zoo heev thiab lubricity, tsim nyog rau kev ua cov ntaub ntawv feem ntau.

7, TiAlN: xiav grey txheej, hardness 3300HV, tshav kub tsis kam mus txog 900 ° C, tuaj yeem siv rau kev ua haujlwm siab.

8, CrN: nyiaj grey txheej, lubrication kev ua tau zoo dua, feem ntau yog siv rau kev ua cov hlau tsis-ferrous.

Cov txheej txheej ntawm cov kais dej muaj qhov cuam tshuam loj rau kev ua haujlwm ntawm cov kais dej, tab sis tam sim no, cov tuam ntxhab thiab cov txheej txheem txheej txheem sib koom ua ke los kawm cov txheej txheem tshwj xeeb, xws li LMT IQ, Walther THL, thiab lwm yam.

Yam uas cuam tshuam rau tapping

A. Tapping khoom

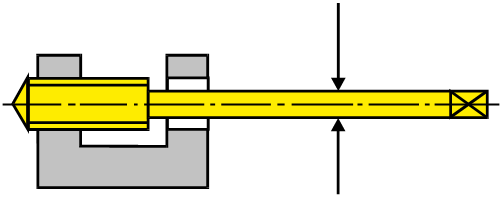

1. Cov cuab yeej siv tshuab: nws tuaj yeem muab faib ua cov txheej txheem ntsug thiab kab rov tav.Rau tapping, ntsug yog zoo dua li kab rov tav ua, thiab kab rov tav ua yuav tsum xav txog seb qhov txias txaus txaus.

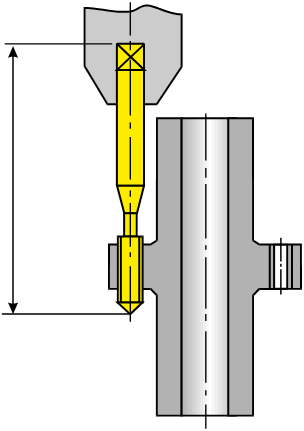

2, tapping shank: tapping yog pom zoo kom siv tshwj xeeb tapping shank, tshuab rigidity, zoo stability yog nyiam mus xaiv synchronous tapping shank, ntawm qhov tsis tooj, kom deb li deb tau xaiv saj zawg zog tapping shank nrog axial / radial nyiaj.Siv square tsav thaum twg los tau, tshwj tsis yog rau me me txoj kab uas hla kais (

3. Txias tej yam kev mob: rau tapping, tshwj xeeb tshaj yog extrusion kais, qhov yuav tsum tau rau coolant yog lubrication> txias;Hauv kev siv tiag tiag, nws tuaj yeem npaj tau raws li cov xwm txheej ntawm lub tshuab cuab yeej (thaum siv emulsion, nws raug pom zoo tias qhov concentration ntau dua 10%).

B. Lub workpiece yuav tsum tau ua

1. Cov khoom siv thiab hardness ntawm cov txheej txheem ua haujlwm: lub hardness ntawm cov khoom siv ua haujlwm yuav tsum tsis sib xws.Nws feem ntau tsis pom zoo kom siv cov kais dej los ua cov khoom ua haujlwm ntau dua HRC42.

2, tapping hauv qab qhov: hauv qab lub qhov qauv, xaiv txoj cai me ntsis;Hauv qab qhov seem qhov tseeb;Hauv qab qhov phab ntsa loj.

C. Kev ua tsis tau

1, ceev: ceev yog muab raws li hom kais dej, cov khoom siv, cov khoom siv thiab cov tawv tawv, qhov zoo thiab qhov tsis zoo ntawm cov khoom siv tapping.

Feem ntau xaiv raws li qhov tsis tau muab los ntawm cov chaw tsim khoom siv kais, qhov ceev yuav tsum raug txo raws li hauv qab no:

▶ lub tshuab cuab yeej rigidity tsis zoo;Loj kais ntaus;Kev ua kom txias tsis txaus;

▶ Tapping cov khoom siv los yog cov tawv tawv tsis sib xws, xws li cov pob qij txha;

▶ Lub kais dej yog lengthened, los yog siv ib tug extension pas nrig;

▶ Supine, sab nraum txias;

▶ Kev tuav haujlwm, xws li lub rooj zaum laum, rocker laum, thiab lwm yam;

2, pub: nruj tapping, pub = 1 pitch / tig.

Saj zawg zog tapping, thiab shank them nyiaj sib txawv yog txaus:

Pub = (0.95-0.98) pitch/revolution.

Qee cov lus qhia txog kev xaiv kais

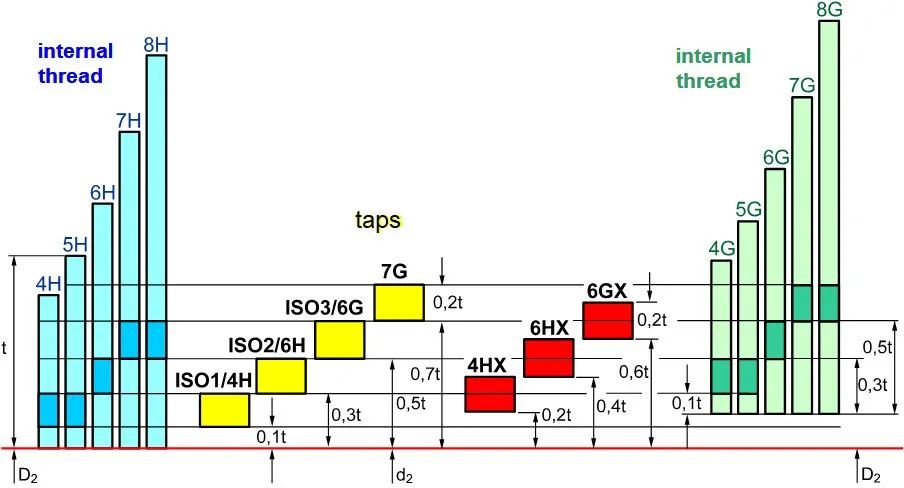

A. Tolerances ntawm cov kais dej ntawm cov qib precision sib txawv

Kev xaiv hauv paus: tsis yog raws li qib precision ntawm cov xov yuav tsum tau machined los xaiv thiab txiav txim siab qib precision ntawm tus kais

▶ Cov khoom siv thiab hardness ntawm cov txheej txheem ua haujlwm;

▶ Tapping khoom (xws li lub tshuab tej yam kev mob, clamping kov, lub nplhaib txias, thiab lwm yam);

▶ Tus kais nws tus kheej raug thiab raug yuam kev.

Piv txwv li: ua 6H xov, hauv kev ua hlau, tuaj yeem xaiv 6H precision kais;Nyob rau hauv cov txheej txheem ntawm grey cam khwb cia hlau, vim hais tias nyob rau hauv nruab nrab txoj kab uas hla ntawm tus kais coj sai, qhov nthuav ntawm lub qhov taub yog me me, yog li nws yog tsim nyog los xaiv 6HX precision kais, lub neej yuav zoo dua.

Nco tseg ntawm qhov tseeb ntawm Japanese kais dej:

▶ Txiav kais OSG siv OH precision system.Qhov sib txawv ntawm ISO tus qauv, OH precision system yuam tag nrho qhov siab band dav los ntawm qhov qis tshaj, txhua 0.02mm raws li qib precision, npe hu ua OH1, OH2, OH3, thiab lwm yam.

▶ Extrusion kais OSG siv RH precision system, RH precision system yuav yuam kom tag nrho qhov dav dav ntawm qhov qis tshaj, txhua 0.0127mm raws li qib precision, npe RH1, RH2, RH3 thiab lwm yam.

Yog li ntawd, thaum hloov OH precision kais nrog ISO precision kais, 6H yuav tsum tsis txhob muab xam raws li qhov sib npaug ntawm OH3 lossis OH4 qib.Nws yuav tsum tau txiav txim siab los ntawm kev hloov dua siab tshiab los yog raws li qhov tseeb ntawm cov neeg siv khoom.

B. Sab nraud ntawm tus kais dej

1. Tam sim no, feem ntau siv yog DIN, ANSI, ISO, JIS, thiab lwm yam.

2, raws li tus neeg siv khoom sib txawv ntawm kev ua haujlwm lossis cov xwm txheej uas twb muaj lawm los xaiv qhov tsim nyog ntev, hniav ntev thiab tuav square loj

3. Kev cuam tshuam thaum ua haujlwm;

Coj mus rhaub xaiv ntawm rau lub hauv paus ntsiab lus

1, hom kev ua xov, metric, British, American, thiab lwm yam .;

2. Hom xov hauv qab lub qhov, los ntawm lub qhov los yog qhov muag qhov muag;

3, txheej txheem workpiece khoom thiab hardness;

4, lub workpiece tiav xov qhov tob thiab hauv qab qhov tob;

5, workpiece xov precision;

6, cov tsos ntawm tus qauv kais dej (tseem ceeb yuav tsum tau cim).

Post lub sij hawm: Sep-22-2022